After over four decades at the forefront of disc brake rotor manufacturing, DBA was determined to develop its very own range of high-quality brake pads. Our pad range is the result of an exhaustive research and development program, having put these pads through their paces on the street, off-road, at the racetrack and our extensive testing equipment.

Our brake pads are direct replacement, i.e. require no modification to your vehicle, and have been designed from the ground up as the perfect match with our long-established and trusted range of disc brake rotors, providing the same level of quality, performance and safety.

Our exhaustive range of brake pads covers over 95% of vehicles on Australian roads and offers options to suit all driving needs, from daily drivers to four-wheel drives and days out on the track . DBA is able to offer a pad and rotor combination to suit your needs.

For our range of performance pads (Street Performance, Xtreme Performance, and Race Performance) we have aligned the colour coding with the THGP paint markings on our 4000 Series and 5000 Series performance rotors. We recommend that you choose your DBA performance brake pad to match the respective rotor paint marking that represents your driving style.

To ensure you choose the perfect DBA brake rotor and pad combination, please refer to the Disc Rotor & Brake Pad Reference Guide, to assist in matching your driving style to the right disc rotor and pad for the job!

In-depth technical information is available at the Q&A section on our website.

Designed for street, commercial, towing and off-road use, our range of brake shoes feature a versatile minimum FF rated friction material which enables a stable and consistent coefficient of friction across a wide temperature range.

|

|

|||

| Friction Material Formulation | Ceramic / Semi-Met | Semi-Met | Semi-Met Carbon Fibre | Semi-Met Carbon Ceramic |

| Copper Content | Copper Free | Copper Free | Low Copper | Contains Copper |

| Application | OE style replacement | Street Performance | High Performance/ Heavy Duty Upgrade/Commercial | High Performance/Race, Circuit, Rally |

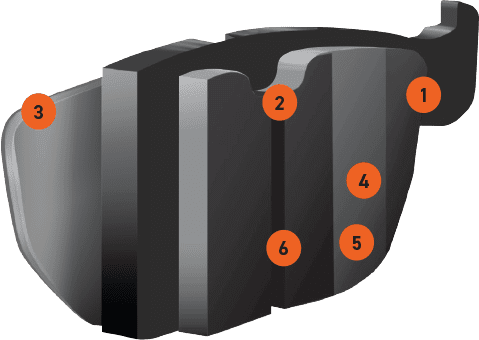

| Chamfer | Yes | Yes | No | No |

| Slot | Yes | Yes | Yes | Yes |

| Shim | Yes | Yes | Yes | No |

| TSP | Post-Cured | Scorched | Scorched | High Temp Scorched |

| Bedding-in Stripe | Yes | No | No | No |

| R90 Certified | No | Yes | Yes | No |

Please wait while you are redirected to the right page...

Disc Brakes Australia is an Australian manufacturer, designer and global marketer of aftermarket and OE-replacement brake rotors and drums, brake pads and shoes, brake cylinders, calipers, brake hoses and fluids, sensors and other ancillary items.

International: (+61-2-9748-0211)

Email: [email protected]

© Disc Brakes Australia 2024 Privacy Warranty Statement Disclaimer